Read enough automotive-related articles on the internet and you will be convinced the internal-combustion engine is being hunted with a fervor typically reserved for villains in Jason Statham movies.

Okay, that conclusion may be extreme—but it holds some truth. Regulations regarding emissions and engine efficiency grow stricter with each passing year and manufacturers are faced with an impossible task: Take a centuries-old design and make it endlessly better—faster, cleaner, stronger, ad infinitum. At some point, progress will plateau, and the cost of ICE experimentation will simply outweigh the incremental gains in efficiency and power. The good news? The internal-combustion engine might have one more trick up its cylinder sleeve.

Fuel, air, and spark—the three things an engine needs to run. Air is one ingredient that it makes sense to leave alone. Fuel type is essentially decided by contemporary infrastructure. (Synthetic fuels are in the works, but we’re thinking of large-scale changes in the ICE design that would extend far beyond the top echelons of motorsport to the everyman (and woman) on the street.) That leaves spark as the low-hanging fruit in this equation. If a different type of ignition could more completely burn the fuel and air mixture, it would not only reduce emissions but also increase efficiency.

Enter plasma ignition.

Traditional spark ignition is very simple.

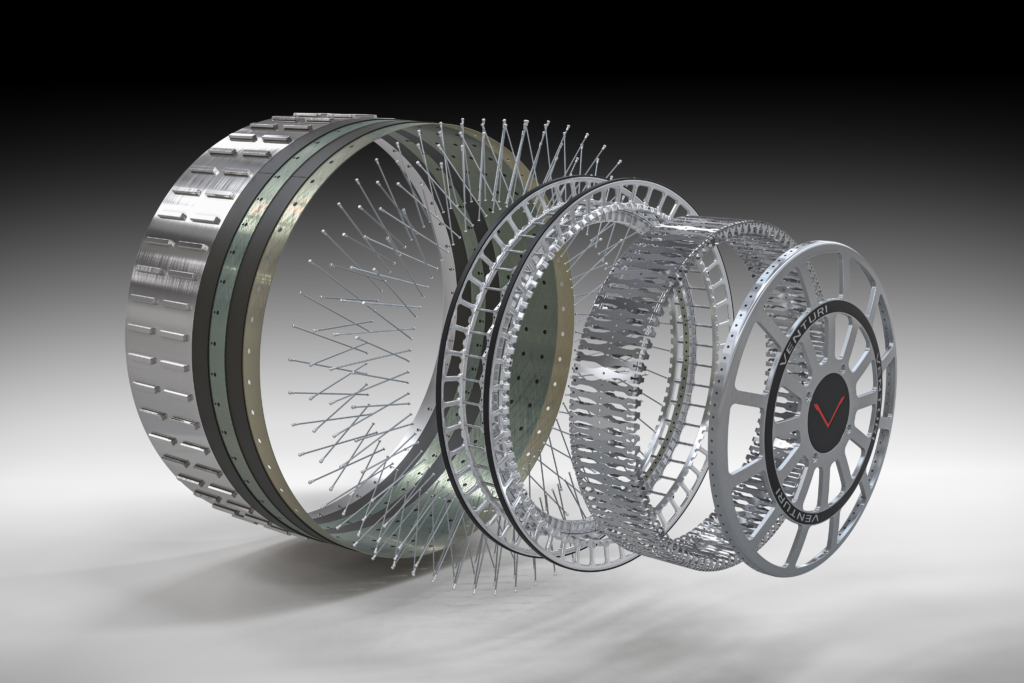

A coil transforms the 12 volts from the car’s charging system into thousands of volts that discharge quickly to jump between the electrode and the ground strap of a spark plug. This forms a sharp but small zap that lights off the chemical chain-reaction that expands the air and fuel mixture to push the piston down and thus rotate the crankshaft. In order for the fuel-and-air mixture to be lit by this type of ignition system, it needs to be fairly close to a stoichiometric mixture; right around 14.7 to 1. That ratio—14.7 grams of air to one gram of fuel—puts a ceiling on efficiency. But here’s where things get interesting.

If we were able to lean out the mixture by adding air but still getting the same in-chamber expansion, and the corresponding force exerted on the piston, efficiency would increase dramatically. A lean mixture is much harder to ignite, though. So hard that you’d need transient plasma to make it happen in any reliable fashion. Technically, the spark on a standard spark plug does create plasma when it ionizes the gasses between the electrode and ground strap; transient plasma takes that small arc and dials it up to 11. If a spark plug is a zap in the chamber, plasma ignition is a TIG welder mounted in a cylinder head.

This much more violent mode of ignition can regularly and predictably ignite extremely lean air/fuel mixtures. One of transient plasma’s most obvious advantages, besides a higher-efficiency combustion cycle, is that relatively low amounts of energy are used to perform a lot of electronic “work.” (The difference between energy and power, for those of you who enjoy recalling high school chemistry class.) The spark itself is not lighting a fire to burn the fuel; rather, a rapid-fire sequence of low-range electronic pulses generates a highly potent electric arc, which then breaks the bonds holding the oxygen molecules together and allows the electrons to shoot out, essentially attacking the hydrocarbons (fuel) and creating combustion. This means we are not waiting on a flame to consume the fuel and, in the amount of time between combustion and exhaust strokes, we get a more complete burn.

The most fascinating part? This technology is not new.

We traced the basic concept to patents from the 1980s, but technology has obviously come a long way since then. Outfits like Transient Plasma Systems, Inc. and Ionfire Ignition are reviving the concept and the reintroduction is timed quite nicely. (If you’ll forgive the pun.) TPS ignition systems have been tested and show a 20 percent increase in efficiency while also decreasing harmful emissions like NOx by 50 percent. Numbers like that aren’t a silver bullet in the ICE gun, but plasma ignition could keep our beloved internal combustion engines on the road longer than we’d expected. TPS claims it is working with manufacturers to integrate its ignition tech into production engines, but we are still a few years away from seeing the fruit of that collaboration.

The internal-combustion engine has undergone constant evolution for centuries, and at this point we’re extracting incremental gains. Plasma ignition could be one of the last significant improvements to be found in the ICE story. Here’s hoping that this ’80s tech, refined for the 21st century’s needs, makes its way onto the streets. For the Silo, Kyle Smith /Hagerty.