Sage Berryman, CEO of ALUULA Composites, has just announced that her company’s super-strong, lightweight polyethylene material is now being used to develop expandable habitats for NASA’s astronauts to live on the moon in 2026.

This small company on Canada’s west coast is playing a big role to help astronauts return to the moon in 2026.

Artemis II crew members (from left) CSA (Canadian Space Agency) astronaut Jeremy Hansen, and NASA astronauts Christina Koch, Victor Glover, and Reid Wiseman walk out of Astronaut Crew Quarters inside the Neil Armstrong Operations and Checkout Building to the Artemis crew transportation vehicles prior to traveling to Launch Pad 39B as part of an integrated ground systems test at Kennedy Space Center in Florida on Wednesday, Sept. 20, to test the crew timeline for launch day. photo: NASA

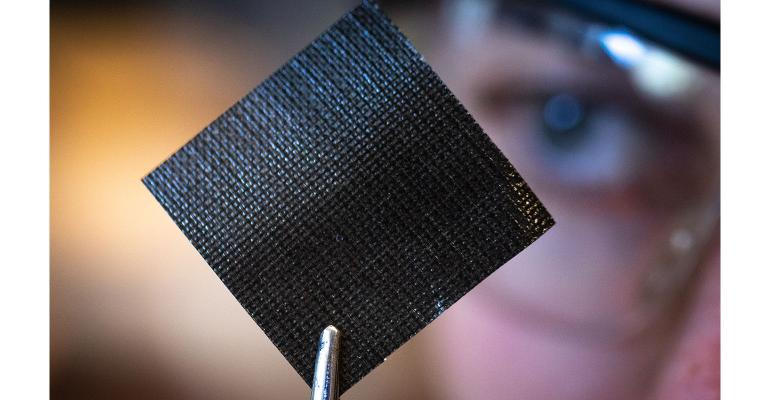

ALUULA Composites recently signed an agreement with Max Space, an American company, to use its innovative composite material to build space habitats on the moon. The company’s ultra-high-molecular-weight polyethylene (UHMWPE) laminate will be used to create a large living and working area for NASA’s astronauts when they return to the moon in September 2026.

The innovative material was selected because it has eight times the strength-to-weight ratio of steel and is extremely durable, which is ideal for space travel.

The Max Space team with their new expandable space habitat. photo: Max Space

The first Max Space inflatable space habitat is slated to launch with SpaceX in 2026. The Max Space inflatables can be delivered into space in very small packages and then unfolded and expanded to create a much larger work space. For the Silo, Paul Clarke.