(Originally published in print and online April5, 2012) Will the new Robot Farmers being launched this July, at the 2nd annual Canada’s Fruit & Veg Tech X-Change, become the future of farming? That question may be answered during planned robotic demonstrations.

Iowa based engineer, David Dorhout believes the Robotic Farmers he invented can help the modern farmer more efficiently produce food.

Increasing labour costs, new stringent health and safety regulations plus the increase of average farm size, are all factors that will measure the practicality and economics for early adopter producers. Dorhout suggests, “Agriculture has been at the forefront of innovation and demand has led to better efficiencies. I think robotic support will become mainstream, starting in the high value horticulture sector”.

Dorhout R&D will be showing off their field and row crop concept Robotic Farmer – “Prospero”. This spider like robot is the working prototype of an Autonomous Micro Planter (AMP) that uses a combination of swarm and game theory. It is meant to be deployed as a group or “swarm”. Dorhout says, “Prospero will eventually have the ability to plant, tend and harvest – autonomously transitioning from one phase to another”. This might not be so far off when you consider that robots are now milking, feeding and cleaning dairy operations around the world. The first milking robot in North America was installed in Ontario in 1999 and just 12 years later they are mainstream with thousands in operation. Thus the question, “Can robotics work on-farm?” has been more than adequately answered if the economics support it.

In addition to Prospero, another highlight of this July’s horticulture trade show in Norfolk County will be Dorhout R&D’s global launch of the new “Aquarius” robot, designed to aid greenhouse operators with dispensing water and other nutrients to plants. Astonishingly enough, this robot will be ready for pre-order at our event.

Have Your Own Farm Invention, Or Know Someone That Does?

Canada’s Fruit & Veg Tech X-Change will be recognizing innovative equipment and tools directly related to on-farm applications.

Enter your custom fabricated tools and equipment for a chance to win one of three cash prizes!

DETAILS

– FREE to enter

– Max 3 items per producer

– Items will be displayed in an outdoor setting

– Cash Prizes for the top 3 entries:

1st – $500, 2nd – $250, 3rd – $100

– Judged by attending producers – based on most creative and best implemented

– Equipment is to be dropped off during the days of Saturday July 7th – Wednesday July 10th

– All equipment must remain at the site for the 3-days of the event – July 12, 13, 14 2012

– Equipment can be picked up during the days of Sunday July 15th – Wednesday July 18th

– Winners will be included in post show press release!

Additional Highlights…

Other event highlights included in the price of admission are:

– “Meet the Buyers” Complimentary Brunch

– “The Wealthy Barber” Celebrity Speaker, David Chilton

– Irrigation Demos

– Cover Crop and New Variety Plots

– Organic XPO, Woodlot XPO

– Educational Speaker Series

– Various equipment demos and much more!

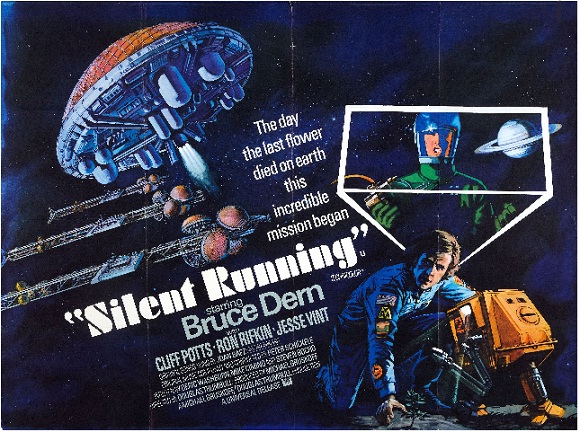

Supplemental- http://en.wikipedia.org/wiki/Silent_Running http://www.dorhoutrd.com/about_us

Automation on the farm [is now really] taking root

I have always found this time of year fascinating as we watch crops burst from the soil. As the days of summer pass all too quickly, a farmer’s thoughts turn to harvest.

As we know, wheat has just been taken off and last week I learned how to drive a combine thanks to Doug, Matthew, and Beverly of Petheram Farms Ltd. Modern combines are packed with hydraulics, Global Positioning Systems (GPS), and computer systems that receive data on things like temperature and moisture of the crop. Imagine what wheat harvesters of the 1800s would think.

Over the past 10,000 years, agriculture has come a long way, but the pace of innovation and change has rapidly accelerated over the past few decades. Think of the days when a farmer went out and applied water, fertilizer, and pesticides uniformly across entire fields. Now, they use the minimum amounts required and can target specific areas or even individual plants to increase crop productivity.

Today, technology on the farm is vital to compete in the global marketplace. Advancements on the farm have changed the way farmers work; ultimately allowing them to reach new levels of efficiency and precision with respect to crop management.

I’ve been in robotic milking barns and absolutely blown away by the cleanliness and technology. Farmers who once missed events like Thanksgiving and Christmas dinners because they had to milk the herd can now sit down to turkey dinner with the rest of the family because robots take care of the heavy lifting. And the farmer can monitor the barn and what’s happening right from his or her phone.

On July 11th I attended the AgRobotics Working Group Demo Day at the Ontario Crops Research Centre on Blueline Road in Simcoe. AgRobotics Working Group is a membership-driven association striving to advance the introduction of innovative agriculture and food robotics and automation systems to improve farm productivity and the quality of our food. The group is funded by the Ontario Ministry of Agriculture and is administered by the Western Fair Association in London. Thank you for an exciting and informative day.

There were many farmers and industry professionals on hand to see demos and presentations from Naio, Vivid Machines, AgXeed, Vitirover, Burro and Harvest Corp Technologies. The latter is a Tillsonburg company that is trialing an autonomous, automatic harvester for use in asparagus crops. The machine operates at 0.6 kilometres per hour, can run 24 hours a day and can therefore harvest 60 spears of asparagus per minute or 30 acres per day. If you check out the company’s website, it cheekily says the machine won’t call in sick or take lunch breaks.

Labour shortages have plagued the industry over the past few years, and undoubtedly robots could help in that regard. At the end of the day a great crop means nothing if it can’t be harvested.

Despite the excitement of the day, concerns over Ontario being left behind were raised. Government must provide greater incentives to home-grown manufacturers of robotic equipment because currently, most of the technology comes from Europe. Cutting red tape and regulation would be a good first step.

In response to my social media, a friend of mine commented her family farm has developed a way to automate strawberry harvest “but the government’s red tape is outrageous.” She emphasized they cannot secure funding for their invention, but had they purchased it third party they would have been funded half the cost. If our farmers and manufacturers are being innovative then it’s time to incentivize them.

Innovation is critical to Ontario’s success in agriculture and if we fall behind on the technology front, we will indeed miss out on opportunities to grow.

Bobbi Ann Brady is the MPP for Haldimand-Norfolk

This is the future. Will the government offer funding to replace offshore workers with automation? Jake